Understand the basic structure before customization! Explaining the fundamentals of ferrofluid feedthroughs

Before introducing a ferrofluid feedthrough, it is very important to understand its structure and working principle. This article explains:

The basic structure and principle of ferrofluid feedthroughs

The working principle of ferrofluid feedthroughs

The importance of custom design

Let’s learn the fundamentals of ferrofluid feedthroughs together.

Basic Structure and Principle of Ferrofluid Feedthroughs

A ferrofluid feedthrough is a sealing component used for rotating parts to prevent gas or liquid leakage. Its most notable feature is the use of a special liquid called magnetic fluid to achieve a non-contact seal. Compared with traditional sealing methods, ferrofluid feedthroughs have low friction, minimal dust, and long service life.

◆ What is a ferrofluid feedthrough? Key features

A ferrofluid feedthrough is a component used to seal rotating parts, using magnetic force to hold the magnetic fluid in place for sealing.

Its main feature is that it produces no friction. Ordinary seals contact the rotating parts, generating friction and wear, shortening lifespan. Ferrofluid feedthroughs use magnetic fluid for non-contact sealing, avoiding friction and wear, making them ideal for long-life, high-vacuum, and clean environments.

Specifically, ferrofluid feedthroughs operate by injecting magnetic fluid into a magnetic circuit composed of magnets, pole shoes, and the rotating shaft. The magnetic fluid is attracted to the gap between the pole shoes and the rotating shaft, forming a circular seal. This seal effectively prevents leakage of gases, vapors, and mists, and is suitable for high-speed rotating components, widely used across industries.

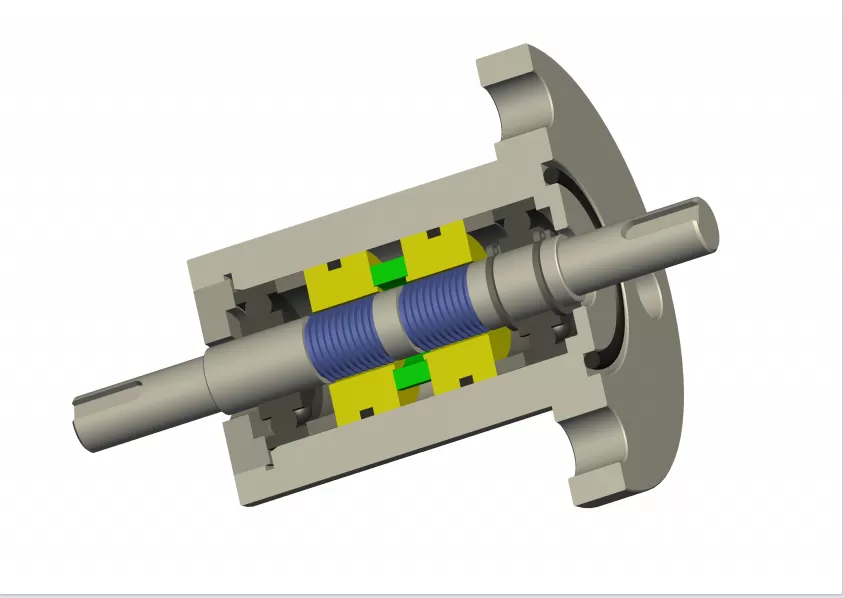

◆ Internal Structure of Ferrofluid Feedthroughs: Magnets, Magnetic Fluid, Pole Shoes, etc.

Ferrofluid feedthroughs mainly consist of four parts: magnets, magnetic fluid, pole shoes, and the rotating shaft, with the following functions:

◆ Magnets

Generate a magnetic field, providing the necessary force to attract and retain the magnetic fluid.

◆ Magnetic Fluid

A special liquid attracted by magnets and retained between the pole shoes and rotating shaft, achieving sealing. Similar to an O-ring, but as a liquid, it produces no friction and does not wear.

◆ Pole Shoes

Magnetic material that forms a magnetic circuit with the magnets, holding the magnetic fluid. Creates a tiny gap around the rotating shaft, which the magnetic fluid fills to form a seal.

◆ Rotating Shaft

A magnetic material shaft that transmits rotational motion. The magnetic fluid is maintained between the shaft and pole shoes, preserving the seal even during rotation.

The magnetic circuit, composed of magnets, pole shoes, and the rotating shaft, fixes the magnetic fluid around the shaft in a circular formation. This ring of fluid acts as a sealing material, producing no friction even at high rotational speeds. A single-layer fluid can withstand limited pressure difference; higher pressure differences can be managed using a multi-layer seal structure.

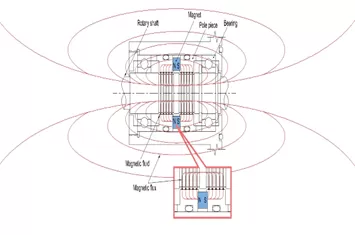

◆ Sealing Principle of Ferrofluid Feedthroughs

Ferrofluid feedthroughs achieve sealing through magnetic fluid and magnetic fields. A strong magnetic field forms between the rotating shaft and the fixed part (pole shoes), attracting the magnetic fluid into a circular seal that acts as a liquid sealing material.

The magnetic fluid consists of nanoscale magnetic particles dispersed in liquid. Under a magnetic field, particles align along magnetic lines, magnetizing the fluid as a whole. Consequently, the magnetic fluid is attracted to regions of strong magnetic force.

Ferrofluid feedthroughs use this property to lock the magnetic fluid between the rotating shaft and pole shoes. The fluid remains liquid, producing no friction even at high speeds, with low heat generation and wear. Its viscosity ensures effective sealing in tiny gaps.

Working Principle of Ferrofluid Feedthroughs

Ferrofluid feedthroughs use the magnetic properties of magnetic fluid to achieve sealing. The fluid contains tiny magnetic particles attracted by the magnetic field. Placing it in a magnetic field formed by magnets and pole shoes allows it to act as a liquid O-ring. The working principle is as follows:

Magnetic Field Formation: Magnets and pole shoes create a strong magnetic field.

Magnetic Fluid Retention: The field attracts and holds the fluid between the rotating shaft and pole shoes.

Sealing Function: The fluid remains firmly in place under the magnetic field, preventing leakage even with a pressure difference, achieving a seal.

Ferrofluid feedthroughs are non-contact seals, with no friction or wear, long service life, suitable for high-vacuum environments, and capable of high-speed rotation.

Importance of Custom Design

Ferrofluid feedthroughs should be custom-designed according to specific customer needs, as different applications and working environments have varying specifications. For example, high-speed rotation requires higher pressure resistance than standard components; high-temperature environments require heat-resistant materials. Custom design considers the following factors:

Load conditions: radial load, axial load, torque, etc.

Applicable fluids: corrosive, viscosity, temperature, etc.

Operating environment: temperature, pressure, vacuum, atmosphere, etc.

Rotational speed: high or low

Pressure resistance: positive, negative, differential

Dimensions: shaft diameter, flange diameter, total length

Through custom design, customers can receive the most suitable ferrofluid feedthroughs for their equipment. Moretec provides custom ferrofluid feedthrough services, and customers uncertain of the appropriate model can consult anytime.

Ferrofluid Feedthrough Consultation – Leave It to Moretec

Ferrofluid feedthroughs are specialized products requiring advanced technology and precise design. Moretec has its own R&D, manufacturing, and sales system, providing stable supply of high-quality products and custom designs for various applications.

Customers may encounter the following issues when introducing ferrofluid feedthroughs:

Issue | Moretec Solution |

Unsure which ferrofluid feedthrough is suitable | Thoroughly understand the application and environment, recommend the most suitable product |

Need special-shaped ferrofluid feedthroughs | Provide custom design based on extensive experience |

Require stable supply of high-quality feedthroughs | Own system ensures high quality and stable supply |

Concerns about post-installation maintenance | Offer comprehensive after-sales support and consultation |

Moretec is committed to providing the best solutions to help customers solve problems. Experienced team provides attentive, detail-oriented service every step of the way.