Vacuum seals, as the name implies, are “sealing devices used to maintain a vacuum state”. Although it is impossible to realize a complete vacuum in reality, in many industrial fields, a state as close to a vacuum as possible is pursued, and various technologies are used to maintain this state.

A “vacuum state” is a space where the pressure is lower than atmospheric pressure. In order to artificially create and maintain a vacuum state in equipment, a high degree of technology is required. This technology is widely used in various fields, such as semiconductor manufacturing processes and vacuum drying. In these processes, it is crucial to maintain the vacuum state.

One of the technologies used to maintain vacuum is “vacuum sealing”. A vacuum seal is a sealing component that maintains a vacuum state by preventing gas leakage. Vacuum seals are an important means of realizing the goal of effectively isolating the vacuum area from the outside atmosphere by means of a sealing structure, even when the shaft is rotating in vacuum equipment or vacuum devices.

There are various types of vacuum seals, and depending on the purpose and scenario, the most suitable type of seal must be selected.

In order to maintain a vacuum, it is usually necessary to use a vacuum pump to extract the air from inside the equipment to create a vacuum. At the same time, a vacuum gauge is used to monitor the pressure inside the equipment to ensure that the vacuum level is stable. Maintaining a vacuum condition is one of the key elements in manufacturing high-quality products.

Vacuum sealing is an indispensable technology for realizing and maintaining a vacuum state. Especially in precision industries such as semiconductor manufacturing, where high precision and cleanliness are required, vacuum seals play a very important role. Their main functions are as follows:

Even when the rotating shaft is running, it can effectively block the gas flow between the vacuum area and the atmosphere.

adopts non-contact sealing, which has less friction and wear and longer service life than traditional mechanical seals.

allows for 100% rotational torque transfer.

When vacuum seals work well, they offer the following advantages:

Improved product quality: A stable vacuum environment helps produce high quality products.

Stable equipment operation: Maintaining a vacuum condition helps equipment operate smoothly for long periods of time.

Improved process efficiency: By optimizing the process flow, overall manufacturing efficiency is improved.

Reduce costs: Reduce the frequency of defective products, reduce the number of maintenance, and thus reduce operating costs.

Improve the working environment: prevent the leakage of hazardous substances and ensure the safety of operators.

Vacuum seals are widely used in many industrial fields, and different applications require seals of different materials, shapes and structures. Correct selection and use of appropriate vacuum sealing devices can not only maximize the performance of the equipment, but also improve product quality and achieve efficient and stable production.

Vacuum seals can be roughly divided into two categories: static seals and dynamic seals, and their characteristics are described below:

Static seals are seals that are used to seal fixed and immobile parts. For example, a static seal is used when two surfaces are in a fixed state and leakage between them needs to be prevented. It can be thought of as a sealing method in which the two surfaces are bolted together.

A static seal usually requires low pressure to seal because there is no relative movement of the sealing parts. At the same time, it is virtually free of friction and wear, resulting in a long seal life. They are available in a wide range of materials and are usually less expensive to manufacture.

Static seals are widely used in vacuum equipment, piping systems and many other areas. As long as the sealing material is reasonably selected, excellent sealing effect can be obtained.

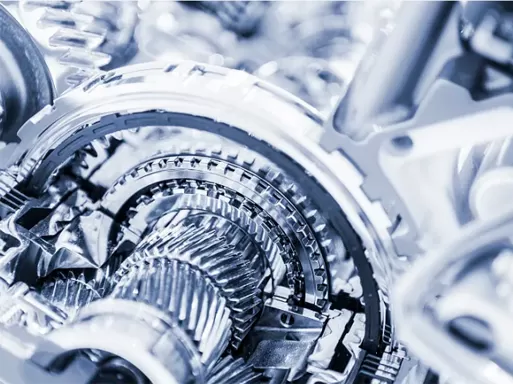

Dynamic sealing refers to the sealing method used to seal the parts where there is relative movement. It can cope with rotary motion, reciprocating linear motion and other forms of motion. Typical applications include “rotary shaft seals” for rotating shafts and “piston seals” for reciprocating pistons.

Compared to static seals, dynamic seals are much more complex in design and application. This is because dynamic seals have to cope with a number of challenges such as friction, wear, temperature changes and pressure fluctuations in relation to the sealing object. All of these factors can affect seal performance and even shorten seal life.

Therefore, dynamic seals must take these factors into account in the selection of materials and structural design to ensure that they maintain excellent sealing effects in service.

MORETEC develops, manufactures, and sells magnetic fluid seal, which are dynamic seals that utilize magnetic fluids. Magnetic air seals offer the following significant advantages:

completely blocks gas exchange between vacuum and atmosphere even at high rotational speeds;

are non-contact seals with low friction and long service life;

is suitable for demanding environments such as high vacuum, high speed and high cleanliness.

This sealing technology is especially suitable for high-end equipment and process scenarios that require very high sealing performance.

Vacuum sealing is an indispensable technology in many industries that require a vacuum condition. It has a wide range of applications, contributing to the manufacture of a variety of products that support our lives.

Semiconductor manufacturing is an extremely precise process in which vacuum seals play an important role. Vacuum seals maintain a vacuum inside the manufacturing equipment and prevent the mixing of impurities. Even a speck of dust or a tiny impurity can seriously affect product quality, so the performance of vacuum seals directly affects the success of semiconductor manufacturing.

As mentioned above, vacuum seals play a vital role in all aspects of semiconductor manufacturing. High-quality semiconductor manufacturing cannot be separated from the excellent performance of vacuum seals.

Organic EL displays use delicate organic materials that are susceptible to moisture and oxygen. Therefore, it is crucial to maintain a high vacuum state during the manufacturing process. To maintain this high vacuum state, vacuum seals play an important role.

These vacuum seals are manufactured using high-precision machining techniques and special materials to ensure high air tightness. As the market for organic EL displays expands, the demand for high-performance vacuum seals is also increasing, with promising growth prospects for the future.

As a result, vacuum seals are widely used in several industries, helping to manufacture the various products that support our lives.

Vacuum technology plays an important role in many industries. MORETEC provides high-quality products, including vacuum seals and magnetic fluid seals, that are based on advanced technology and a wealth of experience. The company offers integrated services from the development and design of vacuum equipment to manufacturing and sales, and is therefore able to provide optimal solutions to customer needs.

If you have a problem with vacuum seals, feel free to consult Moltech Corporation. The vacuum seals we provide are highly gas-tight and can operate stably in a variety of environments. Depending on the customer's needs, we can recommend the most suitable sealing products. In particular, Moltech's magnetic fluid seals excel in high-speed rotary applications and are characterized by “cleanliness,” “high vacuum,” and “long life.

We also accept inquiries about vacuum equipment design, and our experienced engineers will listen carefully to your needs and provide you with the most appropriate design and manufacturing solutions.

Please feel free to contact us. Moltech Corporation will meet your various needs in vacuum technology.