In the production of lithium batteries, vacuum heat treatment furnaces are commonly used to heat battery materials such as anode and cathode materials, separator materials, and current collectors at high temperatures. This process helps remove impurities, improve performance, and enhance stability. Particularly during the heat treatment and baking processes, temperature and environmental control are crucial to ensure the quality and consistency of the product.

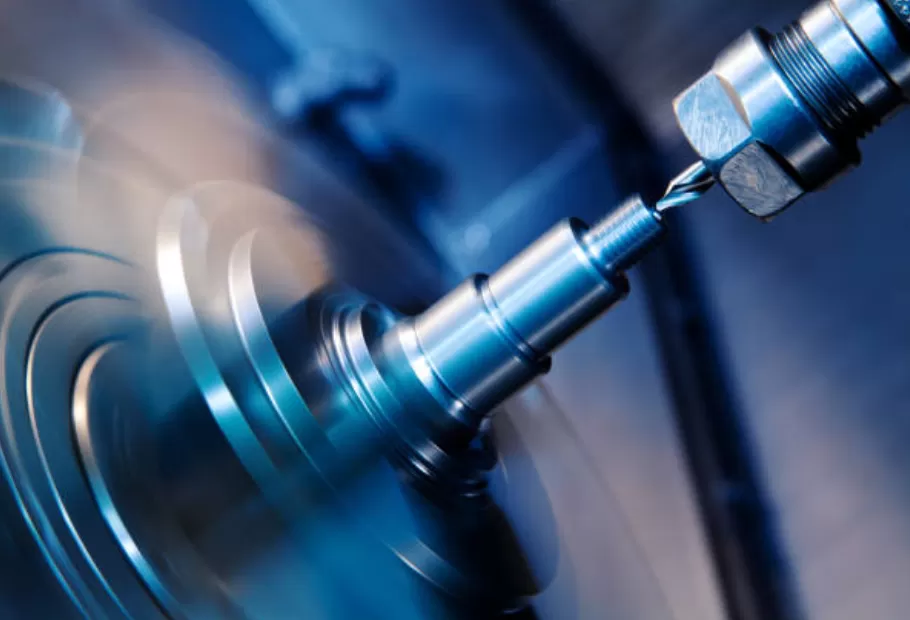

In opto-electronics manufacturing, vacuum heat treatment furnaces are used to process materials such as semiconductors, optical devices, and thin films. These systems often integrate vacuum feedthroughs, including fluid and liquid feedthroughs, to allow the transfer of cooling fluids, gases, or electrical signals while maintaining the integrity of the vacuum environment.

By ensuring stable and contamination-free operation, such feedthroughs play a crucial role in improving the purity, uniformity, and performance of materials — essential for producing laser devices, optical coatings, and optical fibers.