Why do prices vary? Analyzing the relationship between rotary vacuum feedthrough quality and price.

This article is for those who want to understand more about rotary vacuum feedthrough pricing:

• The main factors that cause price fluctuations in rotary vacuum feedthroughs

• Differences in quality and pricing between manufacturers

• How to balance price and performance when making your selection

This can serve as a helpful reference when ordering rotary vacuum feedthroughs.

Reasons for Price Fluctuations in Rotary vacuum feedthroughs

The price of rotary vacuum feedthroughs is influenced by a variety of factors. Here, we’ll explain the primary reasons behind the fluctuations.

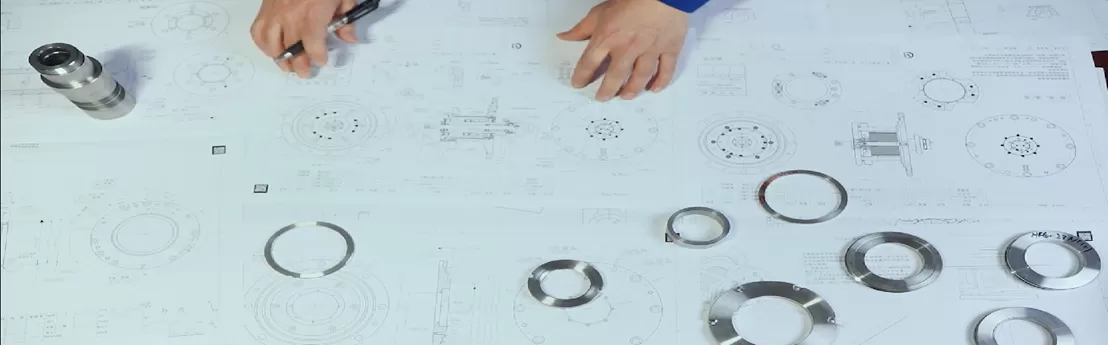

Seal Size and Shape

The price of rotary vacuum feedthroughs is largely determined by their size and structure. Larger seals require more magnetic fluid and larger magnetic circuits, increasing their price.

Seals with complex structures, compared to standard cylindrical ones, require more design and manufacturing processes, thus driving up the cost. If cost reduction is a priority, it’s advisable to select standard models.

Type and Quantity of Magnetic Fluid Used

The price of rotary vacuum feedthroughs also varies depending on the type and quantity of magnetic fluid used. Ferrofluid comes in various types, each with distinct performance characteristics.

For example, rotary vacuum feedthroughs designed for corrosive gas environments require magnetic fluid with higher corrosion resistance, and such specialized fluids tend to be more expensive.

Additionally, the amount of magnetic fluid used depends on the size, structure, and performance requirements of the seal. The larger the required amount of fluid, the higher the price.

Magnetic Circuit Design and Materials

The design and materials of the magnetic circuit are crucial factors affecting the performance of rotary vacuum feedthroughs. The magnetic circuit generates the magnetic field that holds the magnetic fluid in place within the sealing gap.

The design of the magnetic circuit includes factors such as the type, configuration, and shape of magnets. Commonly used magnets include neodymium-iron-boron (NdFeB), samarium-cobalt (SmCo), and aluminum-nickel-cobalt (AlNiCo), each with different magnetic strengths and temperature characteristics.

The materials of the magnetic circuit are usually ferromagnetic metals, such as stainless steel, to improve magnetic flux efficiency. The saturation magnetization strength of these materials directly impacts the sealing performance, so it’s essential to select the appropriate materials based on the intended use.

Operating Environment and Performance Requirements

The price of rotary vacuum feedthroughs also varies significantly based on the operating environment and performance requirements. The higher the performance requirements, the more complex the design and materials needed, which increases the cost.

Key influencing factors include:

• Load

• Rotational speed

• Process gases

• Vacuum level

• Temperature range

If the seal needs to operate in extreme environments, such as ultra-high vacuum or corrosive gases, specialized materials and technologies are required, which can drive up the price.

Production Quantity and Delivery Time

The manufacturing quantity has a significant impact on the unit price. When producing small quantities, setup and preparation costs are spread across fewer units, resulting in higher unit costs. Conversely, mass production helps to reduce unit costs.

If expedited delivery is needed, additional costs may be incurred due to adjustments to the production line or personnel arrangements.

Quality and Price Differences Between Manufacturers

The quality and price of rotary vacuum feedthroughs can vary widely between manufacturers, and the primary reasons for these differences are as follows:

Quality of Magnetic Fluid

The quality of magnetic fluid is a key determinant of sealing performance. High-quality magnetic fluid features longer lifespan, greater stability, and superior performance, but its production costs are higher, leading to a higher price.

Some manufacturers may opt for lower-cost magnetic fluids, which can result in lower performance and shorter lifespan.

Magnetic Circuit Design Capability

Good magnetic circuit design enhances the ability to withstand pressure differences and prevent leaks.

The difference in design capabilities among manufacturers will directly impact the product’s performance and price. For example, magnetic field analysis, thermodynamic analysis, and mechanical calculations involved in ferrofluid lifespan calculation require significant time and resources.

Manufacturing Technology and Equipment

High-precision processing technology and advanced manufacturing equipment are necessary for producing high-quality seals.

Manufacturers with advanced technology can offer higher-performance, more reliable products, but these products usually come at a higher cost. Manufacturers with less advanced technology might offer lower prices, but the quality and reliability of their products might not be guaranteed.

Quality Control Systems

A strict quality control system ensures consistent product performance. Manufacturers who conduct comprehensive tests, including leak tests and pressure differential tests, can offer high-quality products. However, these tests contribute to higher costs, which will be reflected in the price.

How to Balance Price and Performance

When choosing rotary vacuum feedthroughs, it's essential to find a balance between price and performance. The following steps can help you make the best choice:

1. Clarify Essential Performance Requirements

Performance requirements will vary depending on the application. These might include:

• Rotational speed

• Vacuum level

• Temperature range

• Process gases

Clearly defining your needs in numerical terms will help avoid unnecessary expenditure on over-spec products.

2. Choose the Right Magnetic Fluid

Different types of magnetic fluid have varying liquid content and magnetic particles, which result in performance differences.

Moretec offers a variety of magnetic fluids, allowing you to select the most appropriate type based on your needs for the best performance-to-cost balance.

3. Evaluate Long-Term Costs

While products with a lower initial cost might seem attractive, they often have shorter lifespans, leading to more frequent replacements and higher overall costs.

Moretec performs ferrofluid and bearing lifespan calculations to design long-lasting solutions, helping you choose products that provide better long-term value.

By following these steps, you can choose the rotary vacuum feedthrough that best balances price and performance.

Rotary vacuum feedthrough Purchasing Consultation with Moretec

If you're looking for rotary vacuum feedthroughs, feel free to consult Moretec.

We handle everything from design and manufacturing to quality control, ensuring the delivery of high-quality products at competitive prices.

Moretec offers a wide range of magnetic fluids and sealing solutions, optimized for different applications. We provide comprehensive support to ensure long-lasting performance.