This article explains the role of ferrofluid feedthroughs((also known as magnetic fluid seals)) in vacuum environments and introduces “how to select the appropriate ferrofluid feedthrough according to vacuum level, rotational speed, and other conditions.” Choosing the right ferrofluid feedthrough can also improve durability, so special attention is needed when selecting.

The Role of Ferrofluid Feedthroughs in Vacuum Environments! What Are Ferrofluid Feedthroughs Suitable for Vacuum Applications?

Choose the ferrofluid feedthrough suitable for your application! Explaining the role of ferrofluid feedthroughs in vacuum environments.

Introduction

You need to use a ferrofluid feedthrough but don’t know which type to choose. In this case, this article will explain:

• Why ferrofluid feedthroughs are essential in vacuum environments.

• How to select ferrofluid feedthroughs for vacuum applications.

• The durability of ferrofluid feedthroughs in vacuum environments.

Please choose the appropriate ferrofluid feedthrough according to your actual needs.

Why Are Ferrofluid Feedthroughs Essential in Vacuum Environments?

Ferrofluid feedthroughs are mainly used in vacuum environments. This article explains the definition of vacuum environments and the role of ferrofluid feedthroughs.

What is a vacuum environment?

A vacuum is a state where the number of gas molecules in a space is extremely low. Since complete zeroing is difficult in practice, a “pressure state lower than atmospheric pressure” is generally referred to as a vacuum.

Different applications require different levels of vacuum, which are evaluated by vacuum degree.

Vacuum environments are widely used in various fields. For example: vacuum packaging to prevent food oxidation, preventing reactions of oxygen or moisture during electronic component manufacturing, and the indispensable vacuum environment in semiconductor manufacturing in recent years. Other applications include improving insulation in thermos bottles and distillation through substance evaporation. Vacuum has many uses in daily life.

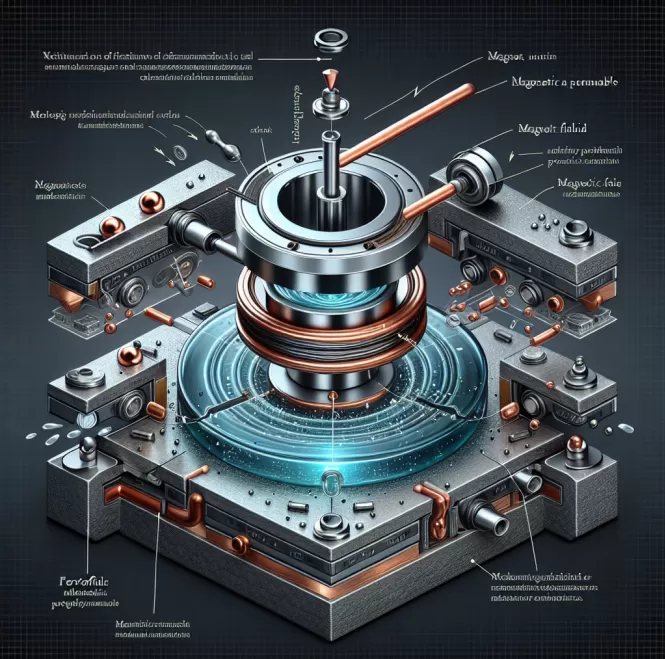

Ferrofluid Feedthrough Solution

In electronic components or semiconductor manufacturing equipment, to maintain a vacuum environment, it is necessary to completely seal the gap between the rotating shaft and fixed parts. Simply sealing would cause contact between the shaft and the fixed part, generating friction, wear, and dust.

Ferrofluid feedthroughs solve this problem by using a special liquid — magnetic fluid — to form a non-contact seal under magnetic force.

Magnetic fluid is a liquid, so it does not produce friction or wear, and dust is minimized. By adjusting the magnetic force, it can handle different pressure differences and maintain high performance even in high vacuum environments.

Therefore, ferrofluid feedthroughs are the best solution for shaft sealing in vacuum environments and an essential technology for achieving high-precision, high-reliability vacuum conditions.

How to Select Ferrofluid Feedthroughs for Vacuum Applications

When selecting ferrofluid feedthroughs for vacuum equipment, factors such as load conditions, achievable pressure or required vacuum level, rotational speed and torque, and temperature environment must be considered. Choosing a ferrofluid feedthrough suitable for each factor can maximize device performance and ensure stable operation.

Load Conditions

When selecting a ferrofluid feedthrough, whether it can withstand the load is crucial. During the design stage, the expected radial load, axial load, and torque must be evaluated, and bearing life calculated to choose a matching ferrofluid feedthrough.

Increased load reduces bearing dynamic life, especially torque, which causes eccentric load or excessive force, significantly affecting lifespan. Therefore, this must be carefully considered in the design.

When selecting a ferrofluid feedthrough, accurately understanding the relationship between load and bearing life is necessary. Choose a product that meets load-bearing requirements to achieve overall system reliability and long-term stable operation.

Vacuum Level and Achievable Pressure

Consider the required vacuum level and pressure when selecting a ferrofluid feedthrough. Choose the appropriate ferrofluid feedthrough according to the needed vacuum level and pressure.

Ferrofluid feedthroughs have performance data showing achievable vacuum and pressure. Generally, higher vacuum means lower pressure and slower exhaust; lower vacuum means higher pressure and faster exhaust. Understand these relationships to ensure the product meets required vacuum and pressure.

Rotational Speed and Torque

For vacuum applications, ferrofluid feedthroughs must accommodate rotational speed and torque. Ferrofluid feedthroughs on high-speed shafts need to withstand high speed while transmitting torque to the shaft.

Different models have varying maximum speeds, rated speeds, allowable torque, and starting torque, depending on the type of magnetic fluid and bearing load.

Refer to these values and consider actual speed and torque conditions. For example, high-speed rotation requires feedthroughs with high maximum speed; high torque environments require models with high allowable torque. Starting torque is the maximum load at startup, and using three times the rated value as a reference is recommended.

Adapting to speed and torque is therefore an important factor in ferrofluid feedthrough selection.

Temperature Environment

Ferrofluid feedthroughs must adapt to the operating temperature. Temperature changes affect magnetic fluid viscosity and magnetic properties, impacting seal performance.

Confirm the operating temperature range. High temperatures reduce viscosity; low temperatures increase it. Extreme temperatures may freeze or evaporate the fluid, losing sealing function.

In high-temperature environments, cooling or using high-temperature-resistant magnetic fluid can prevent evaporation; in low-temperature environments, heating or using fluid with good low-temperature characteristics is recommended.

To select the best ferrofluid feedthrough, consult the manufacturer and provide specific temperature conditions.

Durability of Ferrofluid Feedthroughs in Vacuum Environments

With proper selection and maintenance, ferrofluid feedthroughs can maintain stable performance for a long time. Factors affecting durability include magnetic fluid degradation, material selection, and operating environment.

Magnetic fluid may degrade due to high temperature or corrosive gases, and its lifespan is significantly affected by operating conditions.

Material selection greatly affects durability. In corrosive gas environments, choose corrosion-resistant materials; otherwise, the feedthrough may be damaged.

The operating environment also affects durability. High-speed environments shorten bearing life; external magnetic fields may reduce feedthrough performance.

Regular maintenance, including replacing magnetic fluid and inspecting feedthroughs, can extend life and maintain performance.

Order Ferrofluid Feedthroughs for Vacuum Environments from Moretec

For equipment and instruments requiring high vacuum environments, reliable ferrofluid feedthroughs are indispensable. Moretec specializes in magnetic fluid feedthroughs, providing integrated services from development to manufacturing and sales, and can supply the most suitable ferrofluid feedthrough according to customer needs.

We can design ferrofluid feedthroughs according to customer requirements and provide detailed specifications and performance information for peace of mind.

Ferrofluid feedthroughs play a key role in maintaining high vacuum environments. With years of experience and achievements, Moretec provides high-quality feedthroughs to improve equipment reliability.

We are committed to gaining customer trust through advanced technology, quality management, and stable supply. For ferrofluid feedthroughs suitable for vacuum environments, consult Moretec.