1. Excellent Thermal Conductivity and Power Handling

Moretec's audio ferrofluid replaces air in the speaker voice coil gap, significantly improving thermal conductivity. This reduces voice coil temperature, enhances power handling, and minimizes power compression.

2. Outstanding Damping Effect for Smoother Frequency Response

The audio ferrofluid's viscosity provides mechanical damping to the moving system, smoothing resonance peaks and improving dynamic linearity, resulting in better sound quality.

3. Stable Voice Coil Positioning for Lower Distortion

The audio ferrofluid forms a “liquid O-ring” in the magnetic gap, keeping the voice coil centered, reducing friction and misalignment, and lowering both dynamic and harmonic distortion.

4. Higher Manufacturing Yield and Cost Reduction

Moretec's audio ferrofluid can partially replace spider suspension systems and allows the use of smaller magnets and coils. This simplifies speaker design, increases production yield by 30–60%, and reduces material and manufacturing costs.

5. Multiple Models for Various Applications

Standard Models: Such as P‑110, P‑120, and P‑202, offering a range of saturation magnetization (110–325 Gauss) and viscosity (200 cP to 5000 cP), suitable for both consumer and professional audio systems.

Custom Models: Tailored for high-end or OEM applications, with parameters optimized for specific frequency characteristics, magnetic field strength, and viscosity.

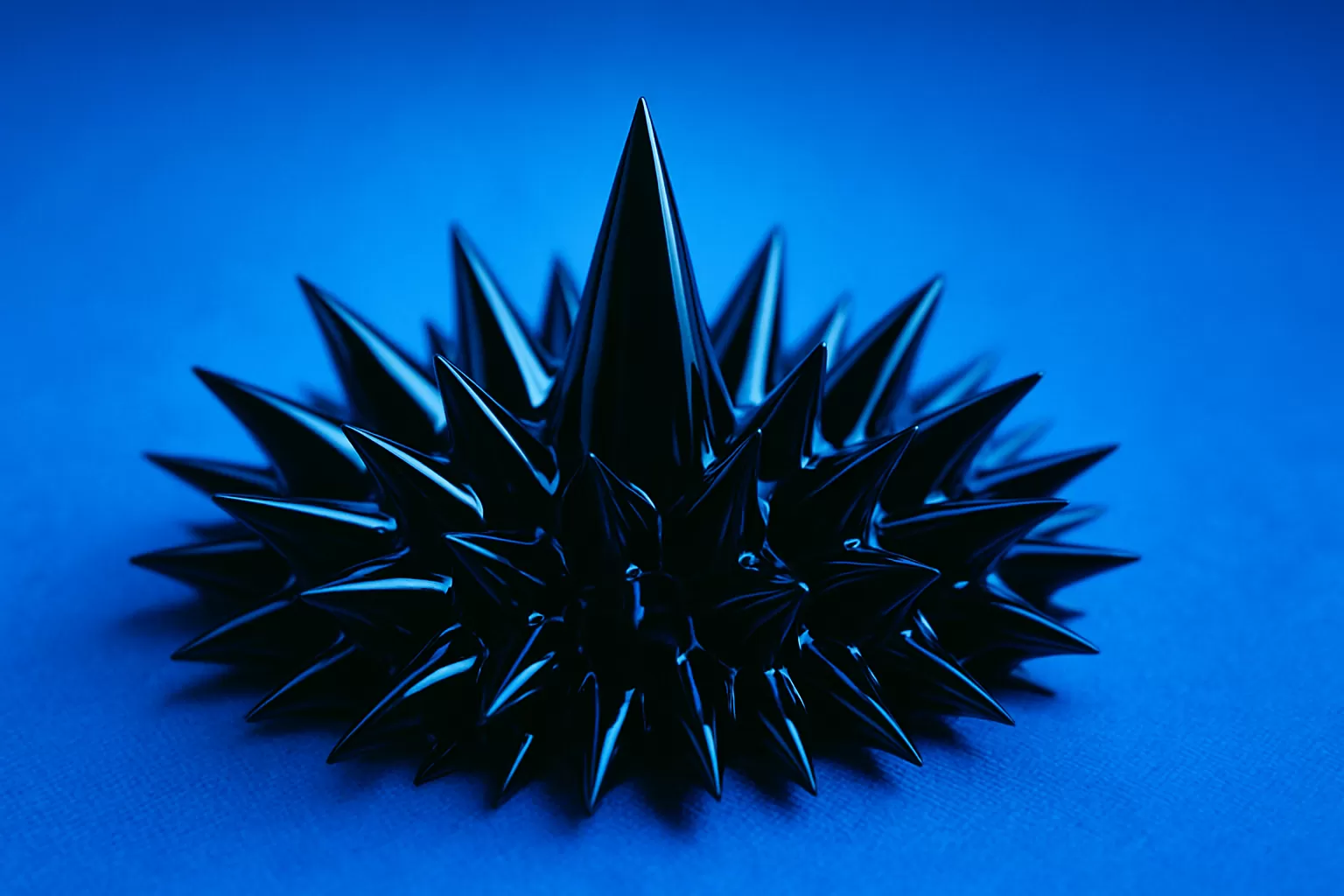

Ferrofluid is an high-quality magnetic liquid that exhibits unique physical properties under a magnetic field. It consists of:

Magnetic nanoparticles (~10 nm in diameter, 1/20th the size of cigarette smoke particles)

Surfactants (to prevent agglomeration)

Carrier liquid (such as hydrocarbon or ester-based oils)

These nanoparticles are uniformly dispersed in the carrier fluid to form a stable colloidal solution. Initially developed by NASA in 1965 for the Apollo program, ferrofluid is now widely used in vacuum seals, loudspeakers, magnetic imaging, and more.

Store at room temperature and pressure. No refrigeration required.

Reseal immediately after use to avoid moisture or contamination.

Do not shake before use to prevent bubble formation.

Ensure adhesive is completely cured and dry before injection.

Avoid leaving syringe in magnetic field during application.

Inject from a fixed point, evenly and in one step—no need for multiple points.

Do not replace standard viscosity ferrofluid with high-viscosity fluid, even in small amounts, as this may impair heat dissipation and shorten product lifespan.

Temperature | MTS Ferrofluid (g/s·cm²) |

150°C | 5.03×10⁻⁹ |

As speaker temperature usually remains below 150°C, lower evaporation directly extends service life.

Temperature Shift (65→80°C) | MTS Viscosity Drop |

<35% |

Minimal viscosity drop ensures consistent damping and voice coil centering performance.

Magnetic Field Strength | MTS Separation Rate |

12,500 Gauss | <0% |

No solid-liquid separation, avoiding splash, ensuring long-term stability.

Adhesive Type | MTS Reaction Rate |

CR-type DC868K | 0% |

No reaction with commonly used centering adhesives, preventing gelation or detachment issues.

| Property | Value |

Appearance | Dark brown liquid |

Viscosity | 75 ~ 5000 cP |

Saturation Magnetization | 100 ~ 600 Gauss |

Specific Gravity | 0.9 ~ 1.2 g/cm³ |

Operating Temperature | 100°C (PAO) / 150°C (Fluorinated) |

Flash Point | 260°C |

P = MTS product code

2 = 200 Gauss saturation magnetization (2 × 100)

10 = 1000 cP viscosity (10 × 100)

Application | Recommended Magnetization |

Tweeters / HF Drivers | 100–200 Gauss |

Midrange / MF Drivers | 200–300 Gauss |

Woofers / Buzzers | >300 Gauss |

Magnetic gap >9000 Gauss → choose 100G ferrofluid

Magnetic gap <9000 Gauss → choose 200G ferrofluid

High-sensitivity units → use lower viscosity ferrofluid

Normal units → higher viscosity is acceptable

There is no universally fixed procedure for magnetic fluid selection. Choices can be made according to the magnetic flux density within the voice coil gap, the physical dimensions of the gap, and the system's frequency response characteristics.

| Item | Classification | Selection Criteria | |

| Type of loudspeaker | Tweeters and high-frequency drivers | Select magnetic fluids with low saturation magnetization (e.g., 100–200 Gauss) | |

| Midrange and full-range drivers | Select fluids with moderate saturation (200–300 Gauss) | ||

| Woofers and alarm devices | Use fluids with relatively high saturation magnetization | ||

| Magnetic flux density within magnetic gap | > 9000 Gauss | Recommend fluids with ~100 Gauss saturation magnetization | |

| < 9000 Gauss | Recommend fluids with ~200 Gauss saturation magnetization | ||

| Others | The damping characteristics of ferrofluids can influence the acoustic frequency response. Use low-viscosity fluids for high-sensitivity transducers; use higher-viscosity fluids where sensitivity is less critical. | ||

To mitigate ferrofluid splashing due to voice coil oscillation, careful consideration of the magnetic fluid’s saturation magnetization is essential.

| Saturation Magnetization (Gauss) | Typical Application Scenarios | ||

| 110–220 | Tweeters, headphones, high-frequency compression drivers, multimedia systems | ||

| 220–330 | Midrange drivers, full-range transducers, mid-frequency compression drivers, alarms | ||

| 330–440 | Woofers, subwoofers, heavy-duty alarm transducers | ||

| Application Context | Recommended Magnetic Fluid Characteristics | ||

| Long-stroke loudspeakers | Use fluids with high saturation magnetization | ||

| Speakers requiring tailored frequency responses | Select fluids with appropriate dynamic viscosity | ||

| Systems operating under strong magnetic fields | Choose fluids with superior colloidal stability | ||

| High-power or long-term reliability requirements | Use fluids with low volatility and minimal evaporation loss |

Due to the inherent viscosity of ferrofluids, mechanical damping is introduced into the acoustic system, altering the frequency response. Therefore, proper selection of viscosity is critical.

| Viscosity Grade | Damping Effect on Voice Coil Motion |

| Low-viscosity type | Produces minimal damping |

| High-viscosity type | Produces greater damping |

| Carrier Fluid Type | Saturation Magnetization (mT) | Dynamic Viscosity @ 27°C (mPa·s) | Application Scope | Moretec Magnetic Fluid Model |

| Synthetic hydrocarbon | 11.0~35.7 | 100~4000 | High-frequency transducers (tweeters) | P-110 |

| 11.0~22.0 | 100~6000 | Tweeters | P-120 | |

| 11.0~27.5 | 70~200 | Compression drivers, tweeters, midrange | P-202 | |

| 11.0~27.5 | 90~1200 | Compression drivers, tweeters, midrange, alarm speakers | P-205 | |

| Synthetic ester | 11.0~33.0 | 60~2,000 | Woofers, tweeters | P-220 |

| 16.5~41.2 | 65~1500 | Woofers, subwoofers, midrange transducers, tweeters | P-210 | |

| 11.0~44.0 | 30~5,000 | Woofers, subwoofers, compression drivers, tweeters, midrange | P-240,P-250 | |

| 11.0~32.5 | 25~200 | Multimedia speakers, headphones | P-302 |

Ferrofluid is composed of three main components: Magnetic nanoparticles, typically magnetite (Fe₃O₄ or γ-Fe₂O₃), Surfactants, which provide colloidal stability by preventing particle agglomeration, and Carrier liquid, such as synthetic hydrocarbons or esters, serving as the dispersion medium.

Incorporating ferrofluid solution into the magnetic gap of a loudspeaker offers multiple technical benefits: Enhances thermal conductivity, improving power handling capability, Modifies and stabilizes the frequency response curve, Dampens unwanted resonances, thereby reducing harmonic distortion and preserving acoustic fidelity.

Ferrofluid used in electroacoustic systems can withstand temperatures up to 200°C, making it suitable for high-power or high-temperature applications.

Under room temperature and sealed storage conditions, the typical shelf life of ferrofluid is approximately 5 years, provided there is no exposure to moisture or oxidizing environments.

Ferrofluid is applied within the magnetic gap (also known as the voice coil gap) of the magnet circuit, surrounding the voice coil to facilitate both magnetic flux conduction and thermal management.