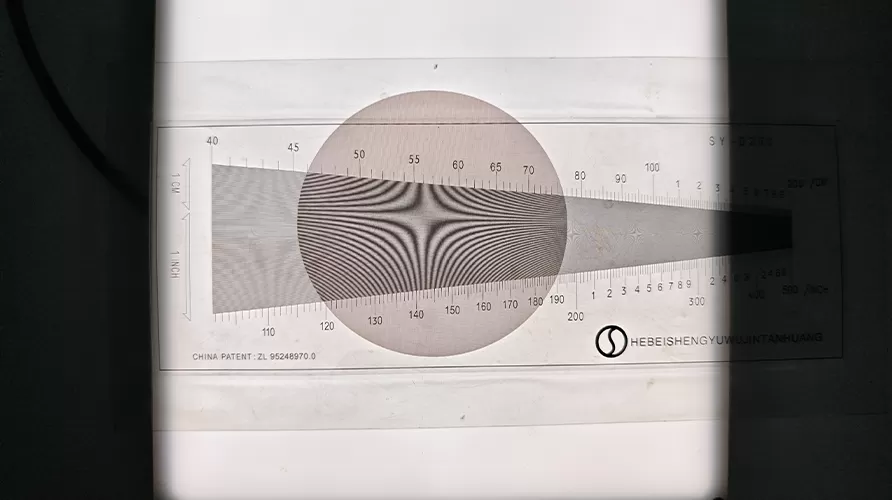

I. Mesh Flattening

Using advanced flat mesh machines, the metal mesh is leveled to achieve a surface unevenness of ≤5mm, meeting strict customer requirements for mesh flatness.

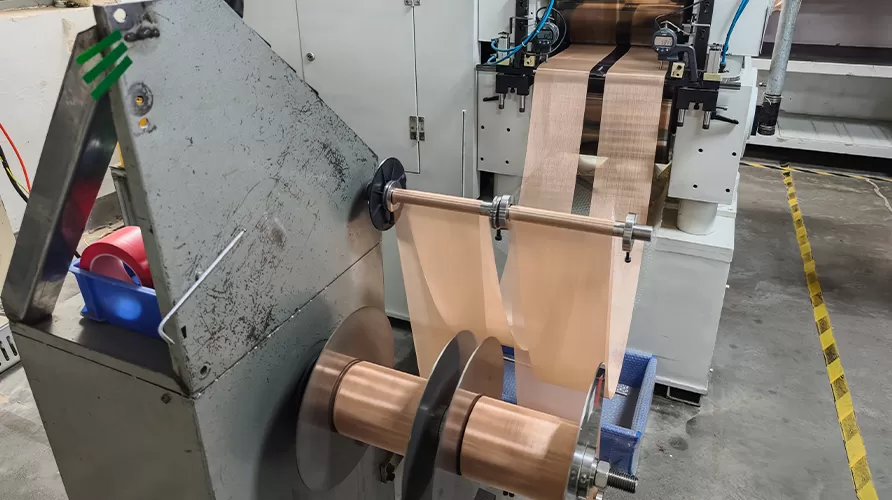

II. Mesh Drawing

Through precision drawing, the mesh tightness and surface uniformity are further improved, reducing weaving irregularities and enhancing overall stability.

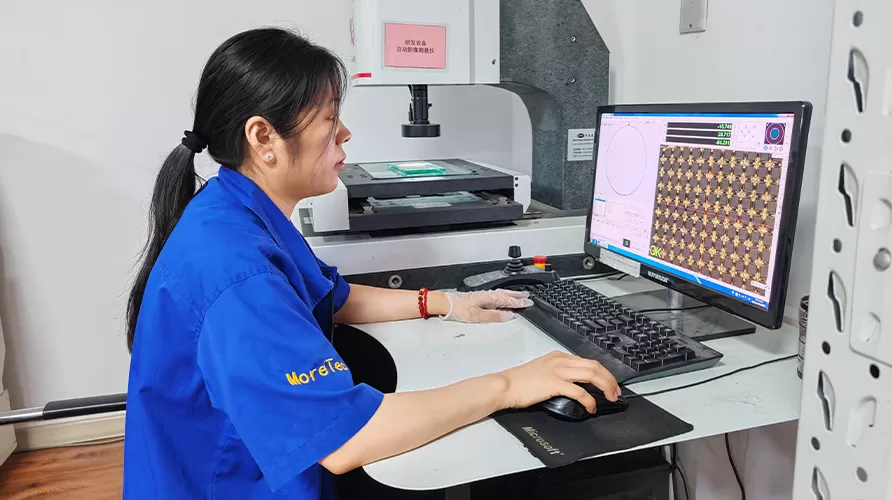

III. Stamping & Cutting

Strip Cutting Machine: Cuts mesh strips as narrow as 5mm, with a tolerance of ±0.5mm according to customer drawings.

Mold Stamping: Ensures bilateral gap precision of 0.004–0.006mm, roundness of 0.003mm, and outer diameter tolerance within ±0.1mm.

Laser Cutting: Program-controlled laser cutting allows both regular and irregular mesh shapes with precision up to ±0.1mm.

IV. Rolling Process

Precision rolling ensures consistent thickness, flatness, and smooth edges, achieving the required specifications for cryo mesh performance.

V. Vacuum Heat Treatment

Using high-temperature vacuum furnaces, stainless steel cryo mesh is heat-treated to enhance mechanical strength and meet customer-defined requirements.

VI. Customization

Mesh size, aperture, material, and specifications can all be customized to suit diverse industrial applications.

Excellent mechanical performance at cryogenic temperatures

Efficient filtration of particles and oil vapor to stabilize vacuum systems

Optional materials: stainless steel and phosphor bronze for corrosion resistance and conductivity needs

High-strength woven structure with low deformation risk

Easy installation and extended service life

| Mesh for Cryo | |||||||

| Normal aterture sizes ( mm ) | Wire Diameter( mm ) | Screening Area (%) | weight of unit area ( kg /m2) | equivalent | |||

| R10 | R20 | R40/3 | phosphor -bronze | stainless steel | meshes ( M / inch) | ||

| 0.125 | 0.125 | 0.125 | 0.09 | 37 | 0.536 | 0.475 | 118.14 |

| 0.08 | 41 | 0.445 | 0.394 | 123.9 | |||

| 0.071 | 44 | 0.367 | 0.325 | 129.59 | |||

| 0.063 | 48 | 0.3 | 0.266 | 135.1 | |||

| 0.056 | 51 | 0.247 | 0.219 | 140.33 | |||

| 0.05 | 34 | 0.203 | 0.18 | 145.14 | |||

| 0.112 | 0.08 | 38 | 0.475 | 0.42 | 132.29 | ||

| 0.071 | 41 | 0.393 | 0.318 | 138.8 | |||

| 0.063 | 44 | 0.327 | 0.286 | 145.14 | |||

| 0.056 | 48 | 0.379 | 0.336 | 151.19 | |||

| 0.05 | 33 | 0.22 | 0.195 | 156.79 | |||

| 0.106 | 0.08 | 36 | 0.49 | 0.434 | 136.56 | ||

| 0.071 | 39 | 0.455 | 0.359 | 143.5 | |||

| 0.063 | 43 | 0.334 | 0.296 | 150.29 | |||

| 0.056 | 46 | 0.275 | 0.244 | 156.79 | |||

| 0.05 | 31 | 0.2 | 162.82 | 162.82 | |||

| 0.1 | 0.1 | 0.08 | 34 | 0.506 | 0.449 | 141.11 | |

| 0.071 | 38 | 0.42 | 0.372 | 148.54 | |||

| 0.063 | 41 | 0.346 | 0.307 | 155.83 | |||

| 0.056 | 44 | 0.287 | 0.254 | 162.83 | |||

| 0.05 | 31 | 0.21 | 169.33 | 169.33 | |||

| 0.09 | 0.09 | 0.071 | 35 | 0.446 | 0.395 | 157.76 | |

| 0.063 | 38 | 0.369 | 0.327 | 166 | |||

| 0.056 | 41 | 0.306 | 0.271 | 174 | |||

| 0.05 | 44 | 0.254 | 0.225 | 181.43 | |||

| 0.045 | 31 | 0.213 | 0.189 | 188.15 | |||

| 0.08 | 0.08 | 0.063 | 35 | 0.395 | 0.35 | 177.62 | |

| 0.056 | 38 | 0.328 | 0.291 | 186.78 | |||

| 0.05 | 41 | 0.274 | 0.243 | 195.38 | |||

| 0.045 | 44 | 0.23 | 0.204 | 203.2 | |||

| 0.04 | 30 | 0.19 | 0.168 | 211.7 | |||

| 0.075 | 0.063 | 33 | 0.41 | 0.363 | 184 | ||

| 0.056 | 36 | 0.341 | 0.302 | 194 | |||

| 0.05 | 39 | 0.284 | 0.352 | 203.2 |

Cryo Mesh is widely used in cryopump systems of MRI (Magnetic Resonance Imaging) devices and cryogenic pumps. It prevents contaminants from entering the cryogenic chamber, helping maintain a stable vacuum environment and ensuring reliable equipment performance.